Image sensor

An image sensor or imager is a sensor that detects and conveys information used to make an image. It does so by converting the variable attenuation of light waves (as they pass through or reflect off objects) into signals, small bursts of current that convey the information. The waves can be light or other electromagnetic radiation. Image sensors are used in electronic imaging devices of both analog and digital types, which include digital cameras, camera modules, camera phones, optical mouse devices, medical imaging equipment, night vision equipment such as thermal imaging devices, radar, sonar, and others. As technology changes, electronic and digital imaging tends to replace chemical and analog imaging.

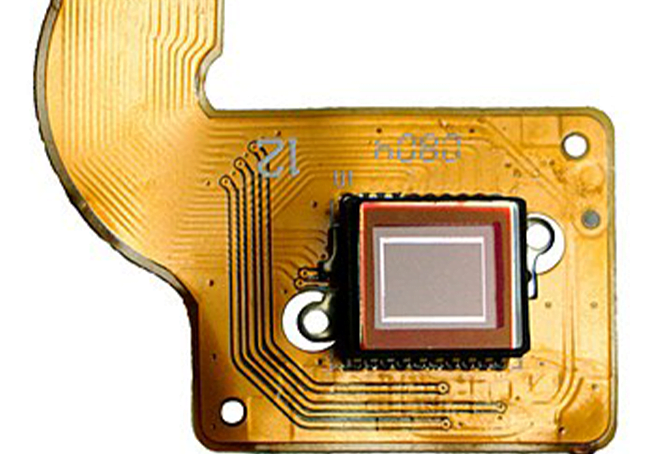

The two main types of electronic image sensors are the charge-coupled device (CCD) and the active-pixel sensor (CMOS sensor). Both CCD and CMOS sensors are based on metal–oxide–semiconductor (MOS) technology, with CCDs based on MOS capacitors and CMOS sensors based on MOSFET (MOS field-effect transistor) amplifiers. Analog sensors for invisible radiation tend to involve vacuum tubes of various kinds, while digital sensors include flat-panel detectors.

The two main types of digital image sensors are the charge-coupled device (CCD) and the active-pixel sensor (CMOS sensor), fabricated in complementary MOS (CMOS) or N-type MOS (NMOS or Live MOS) technologies. Both CCD and CMOS sensors are based on MOS technology, with MOS capacitors being the building blocks of a CCD,[5] and MOSFET amplifiers being the building blocks of a CMOS sensor.

Cameras integrated in small consumer products generally use CMOS sensors, which are usually cheaper and have lower power consumption in battery powered devices than CCDs.[8] CCD sensors are used for high end broadcast quality video cameras, and CMOS sensors dominate in still photography and consumer goods where overall cost is a major concern. Both types of sensor accomplish the same task of capturing light and converting it into electrical signals.

Each cell of a CCD image sensor is an analog device. When light strikes the chip it is held as a small electrical charge in each photo sensor. The charges in the line of pixels nearest to the (one or more) output amplifiers are amplified and output, then each line of pixels shifts its charges one line closer to the amplifiers, filling the empty line closest to the amplifiers. This process is then repeated until all the lines of pixels have had their charge amplified and output.

A CMOS image sensor has an amplifier for each pixel compared to the few amplifiers of a CCD. This results in less area for the capture of photons than a CCD, but this problem has been overcome by using microlenses in front of each photodiode, which focus light into the photodiode that would have otherwise hit the amplifier and not been detected.[9] Some CMOS imaging sensors also use Back-side illumination to increase the number of photons that hit the photodiode. CMOS sensors can potentially be implemented with fewer components, use less power, and/or provide faster readout than CCD sensors.[11] They are also less vulnerable to static electricity discharges.

Another design, a hybrid CCD/CMOS architecture (sold under the name “sCMOS”) consists of CMOS readout integrated circuits (ROICs) that are bump bonded to a CCD imaging substrate – a technology that was developed for infrared staring arrays and has been adapted to silicon-based detector technology. Another approach is to utilize the very fine dimensions available in modern CMOS technology to implement a CCD like structure entirely in CMOS technology: such structures can be achieved by separating individual poly-silicon gates by a very small gap; though still a product of research hybrid sensors can potentially harness the benefits of both CCD and CMOS imagers.